LOYALTY.

PARTNERSHIP.

QUALITY.

Quality Policy

LaserCraft earns customer loyalty by delivering the best service possible.

LaserCraft delivers this service with the best team; meeting customer expectations and continually improving.

LaserCraft Pillars of Success

LaserCraft is a one stop fabrication company specializing in custom fabrication of carbon steel, stainless steel and aluminum parts. From flat sheet to structural and architectural shapes, we are a premium supplier for cutting, forming, machining, welding, and assembly. ISO certified quality and world class customer support are what set us apart as an industry leader. These are the pillars of success that the LaserCraft team has chosen to build on.

Experienced and dedicated Staff

LaserCraft’s experienced team is dedicated to providing solutions that go beyond simply fabricating a component. A top down philosophy of “cost of ownership” means that the LaserCraft team is dedicated not only to taking pride and ownership in our customers’ parts, but also in their processes.

Support

From the lobby to our shipping docks we take pride in making each employee at LaserCraft available to help with customer support. We value our employee’s knowledge and utilize that knowledge to assist in solutions that accommodate our customer’s needs.

Partnership

Long term customer partnerships are our priority. By maintaining consistent value added partnerships with our customers, we understand their process and are better able to provide the innovative solutions they require.

Loyalty

We believe that loyalty to our customers is critical to our mutual success. As a result we are proud of our loyal customer base.

Quality

Our company uses the phrase “Safety, Quality, Productivity” to measure success.

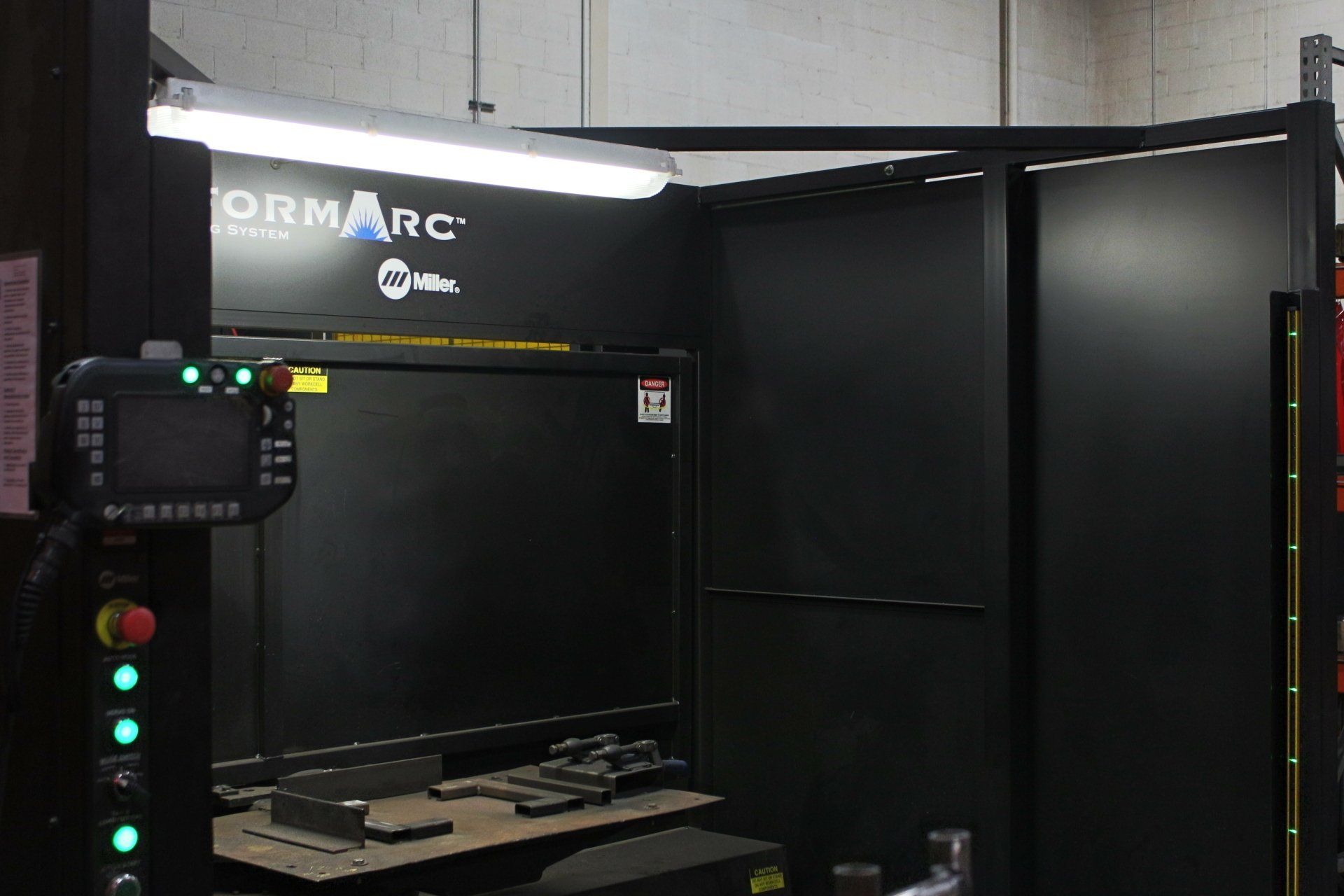

Investment

LaserCraft continues to invest in a way that allows us to remain on the technological cutting edge of our industry. We believe that continuous improvement, investment in technology, and an effective training program are all key to the safety of our employees and productivity of our company.

Commitment

LaserCraft is committed to ensuring our employees a safe, pleasant work environment as well as the elite customer service our customers have come to expect.

Safety

Paramount is your safety and the safety of those around you.

Quality

The quality of the product and service we provide is secondary only to that.

Efficiency

Efficiency in productivity is a direct result of our success with numbers one and two.

How can we serve you?

World Class Customer Service

We are proud to be a locally owned business meeting our customer’s needs for 25 years. We ensure timely and detailed communication in order to meet your expectations on every order.

Friendly and knowledgeable Customer Service Specialists will assist you throughout the process, including: routing and expediting quote requests, providing and maintaining price and delivery information, and acknowledging customer orders and providing updates as changes occur.

At LaserCraft, your satisfaction is our priority.

Company History

Tracking the LaserCraft history of Growth & Innovation

Processes and Capabilities

Lasercrafts’ facility is equipped to produce a wide range of jobs in multiple industries. Each process is performed with the latest and best technologies available on the market today. This gives us the ability to manufacture prototypes, small quantity orders, high volume OEM part orders and large multi-level assemblies. We are always pursuing value added services and increased vertical integration to service our customers’ needs.

Lasers

LaserCraft currently operates seven Mazak lasers that provide cutting edge technology. Our lasers range from new 4kw and 8kw fiber lasers with automation to three 4000W CO2 lasers with FMS automation. One 1000W laser and one 2500W Space Gear with 3D cutting capabilities. Our laser technology and automation coupled with our advanced software provides maximum efficiency.

Laser Capabilities: Material Max Thickness, Steel 1 inch, Stainless ½ inch, Aluminum 3/8

inch

Punching

LaserCraft has invested in a Muratec Motorum 2558 which provides the latest in CNC punching technology. The Muratec provides outstanding manufacturing speed and accuracy. It also offers versatile secondary work stages such as forming, tapping, and etching. We also operate an Amada Pega CNC Turret Punch, a Geka 55 ton Iron Worker, as well as a Whitney Single Station Punch. Having these punching capabilities on hand gives us options to best process customer parts.

Cutting

Along with our laser and turret cutting, LaserCraft Technologies offers a wide variety of cutting metal and structural material. We process this cutting using our Accushear shear, automatic horizontal band saws, and a semi-automatic cold saw. LaserCraft also offers the latest in Marvel Saw CNC technology including auto feed, and nesting for improved yield.

Forming

LaserCraft has invested in state-of-art, CNC Accurpress and Safan press brakes that incorporate

Precision ground and hardened forming dies. We have six press brakes ranging from 60 ton for smaller,

lighter gauge jobs, up to 400 tons for the larger, thicker material. Our 195, 235, and 400 ton Accurpress

brakes use a 6 axis back gauge system that make multi-degree bends and muiltiple bend lenths easier by

significantly reducing set up times.

Machining

LaserCraft Technologies is proud to provide full machining capabilities. With four CNC turning centers, five CNC milling centers, and a complete manual milling shop we can produce a wide variety of parts for our customers.

Finishing

Finish is very important to our customers. As a result LaserCraft has invested in four timesavers, two vibratory finishing mills for stainless material, a vibratory parts dryer, and bead blasting for stainless parts large and small, as well as a stroke sander.

Equipment List

Laser Cutting

MAZAK NEXUS FIBER (8KW) LASER WITH LOAD/UNLOAD AUTOMATION

MAZAK OPTIPLEX FIBER (4KW) LASER WITH LOAD/UNLOAD AUTOMATION

MAZAK FMS 20 SHELF AUTOMATIC MATERIAL LOAD / UNLOAD SYSTEM

1 MAZAK HTX 4000 WATT 5 X 10

1 MAZAK MK II 4000 WATT 5 X 10

1 MAZAK MK II 4000 WATT 5 X 10 STAND ALONE

1 MAZAK 1000 WATT 4 X 8 STAND ALONE

1 MAZAK 2500 WATT SPACE GEAR STAND ALONE 3D / TUBE CUTTING

Tube Fabrication

1 BAILIEGH RDB-325 TUBE BENDER WITH ROTARY POSITIONING TABLE

1 RUSCH TUBE BENDER

1 WINTON RD20 CNC TUBE BENDER

1 BAILEGH TN-800 TUBE AND PIPE NOTCHER

2 ROLL BENDING MACHINES

Punching

1 MURATEC MOTORUM 2558 THICK TURRET PUNCH PRESS

1 AMADA PEGA 244 THICK TURRET PUNCH PRESS

1 WHITNEY SINGLE STATION PUNCH PRESS

1 GEKA 50A 55 TON IRON WORKER

Saw Cutting

1 HYD-MECH S-23A HORIZONTAL BAND SAW W/AUTOMATION

1 HEM SAW VT100LM-60 VERTICAL BAND SAW

1 CLAUSING C112AX HORIZONTAL BAND SAW W/AUTOMATION

2 FMB HORIZONTAL BAND SAWS

1 MARVEL 1250 CNC SAW WITH AUTO FEED ATOMATION WITH NESTING CAPABILITY

Forming

1 SAFAN E-BRAKE 5-AXIS CNC (100 TON X 10’)

ACCURPRESS ACCELL CNC PRESS BRAKE (400 TON X 12’)

1 ACCURPRESS ACCELL CNC PRESS BRAKE (235 TON X 12’)

1 ACCURPRESS ACCELL CNC PRESS BRAKE (190 TON X 12’)

1 ACCURPRESS ACCELL CNC PRESS BRAKE (100 TON X 8’)

1 ACCURPRESS ACCELL CNC PRESS BRAKE (60 TON X 6’)

1 ACCURPRESS CNC PRESS BRAKE (175 TON X 12’)

1 FACCIN CNC 4 ROLL DOUBLE PINCH PLATE ROLL (80”)

1 FACCIN 3 ROLL PLATE ROLL (60”)

1 ROUNDO ROLL BENDER

1 DAKE HYDRAULIC PRESS

Machining

1 MAZAK QT250 MY CNC TURNING CENTER WITH HIGH CAPACITY PARTS CATCHER

1 MAZAK QT250 MY CNC TURNING CENTER WITH HIGH CAPACITY PARTS CATCHER

1 MAZAK QT250 MSY CNC TURNING CENTER W/SUB SPINDLE AND 4’ BAR FEEDER

1 DAEWOO PUMA CNC TURNING CENTER

1 MAZAK NEXUS 700D/40-II CNC VERTICAL MACHINING CENTER

1 HAAS VF-4 CNC VERTICAL MACHINING CENTER

1 HAAS VF-3 CNC VERTICAL MACHINING CENTER

1 HAAS VF-2 CNC VERTICAL MACHINING CENTER

1 HAAS DM-2 CNC VERTICAL MACHINING CENTER

3 CONVENTIONAL MILLS

3 CONVENTIONAL LATHES

1 HARIG SURFACE GRINDER

1 KEYSEAT BROACHING MACHINE